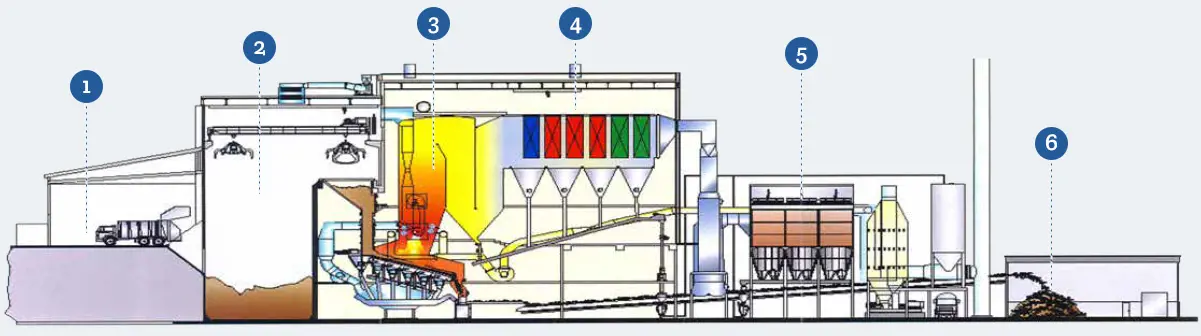

This definition covers the site and the entire incineration plant including all incineration lines, waste reception, storage, on site pretreatment facilities, waste-fuel and air supply systems, boiler, facilities for the treatment of exhaust gases, on-site facilities for treatment or storage of residues and waste water, stack, devices and systems for controlling incineration operations, recording and monitoring incineration conditions.

-

Delivery and incineration

Acceptance of 600 tons of waste per day,up to 70% of it delivered by railway. The volumereduction of the waste is up to 90% and massreduction of about 70%. Therefore the plant saves volumes desposed on landfills and provides a clean alternative to fossil fuels.

-

Bunker

Storage of 4,000 tons of waste, which represents the capacity for one week.

-

Grate kiln

Incineration of 20t/h waste on a watercooled grate kiln.

-

Steam boiler

The combustion process converts waste to steam. Production of 68t/h steam with 405°C and 42 bar. Steam drives a turbine to produce electricity.

Turbine

Production of 15MW electricity with 20kV capable of powering 30,000 households.

-

Offgas cleaning

Dry offgas cleaning and polution control system with activated adsorption, bag filter and NOx reduction clean emissions.

-

Slag stock

3,000 tons/year of metals are recycled from the bottomash (45,000 tons/year).

Animation