What are the advantages and disadvantages of incineration process?

General discussions about incinerating of wastes are accompanied often by contra dictionary information about pros and cons. In reality disadvantages of incinerating are limited due to the fact of very strict requirements within the approval process and a following operation phase of modern incineration plants. Risk factors that could harm human environment are eliminated or definitely strictly controlled. The advantages of waste incineration can be recognized in all circumstance by everyone. Nevertheless, there still exist many myths about incineration.

In order to move waste management away from the cheapest solution, landfilling, towards adequate sorting, recycling and treatment technologies, legal regulations are needed. If cheap landfilling is the only alternative to recycling, like it is the case in many southern and south-eastern European countries, the economic incentive to divert resources, which would otherwise be recycled, to landfills is high. Incineration costs about four times as much as landfilling. The relationship between landfilling, WtE and recycling in the European Union countries is well known among practitioners. It shows that those countries with a highly developed waste management system, characterised by high recycling rates, have the highest share of WtE and the lowest percentage of landfilling. Many European countries already introduced a landfill ban, which prohibits the disposal of untreated MSW. Two alternatives to landfilling of MSW emerged, on the one hand Mechanical-Biological-Treatment (MBT) of waste and on the other hand Thermal Treatment. The treatment costs for these processes are in a similar range. MBT is a very energy intensive process requiring additional treatment. The high calorific material is split from the low calorific material and incinerated, in e.g., cement kilns, whereas the low calorific fraction is stabilized in the biological treatment phase and afterwards disposed. Waste to Energy acts as a final sink, it destroys harmful substances providing a “kidney function” for the waste management system and significantly reduces the mass and volume of the waste, furthermore it generates electricity and heat.

Incineration plants can be located close to residential areas, e.g., in industrial parts of a city, which are the centres of production of waste. This helps to reduce the volume of traffic, pollution, noise and of course the costs for the waste transportation. Furthermore, compared to landfills, waste to energy plants enhance air quality and reduce bad odours.

On the other hand, a remote location makes it often difficult or impossible to utilise the heat produced in a WtE plant along with electricity. This decreases the plant energy efficiency and positive ecological impact (replacing fossil fuels used in heating system).

Many incinerators have their own rail connection: In the FCC incinerator in Zistersdorf a part of the input material is transported by railway transport resulting in less impact to the environment. If this is not given, additional traffic is of course necessary. However, every project is decided on a case-to-case base in the EIA procedure and can have a different outcome.

In general, waste to energy can drive social and cultural opportunities in all communities; studies have shown, that in the waste recovery sector each single employee creates three more jobs in the concerned region:

- Additional workplaces (e.g., Zistersdorf: during construction ca. 150 workers, for operation ca. 40 employees, but also indirectly via collection or sorting before incineration or for maintenance)

- Higher incomes for employees due to offering jobs to more skilled people

- Higher benefits along the whole value chain in the region (e.g., for construction sector, hotels/restaurants, industrial services)

- Infrastructure is improved (train connection, roads)

- Higher tax incomes.

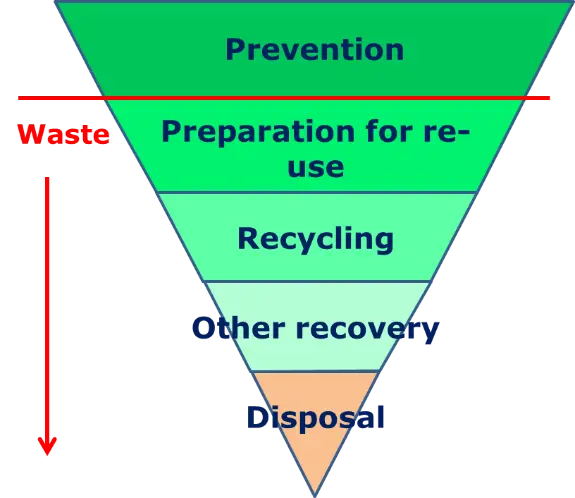

Worldwide, 216 Mio. tons of MSW (municipal solid waste) are incinerated per year. During incineration, thermal waste to energy can utilise the energetic value in waste to generate heat and/or electricity. 1% of renewable energy globally is produced through the biogenic component of the waste. WtE is carbon neutral when it comes to the combustion of the biogenic fractions such as paper, wood, and food waste. If landfilled, the degradation of such fractions would release methane, a more significant greenhouse gas than CO2, in situations where full capture of the landfill gas is not achievable. The official waste hierarchy according to EU law (and its respective transpositions into national law) is distinguishing between recovery and disposal activities. In regard to this, a Waste-to-Energy plant recovers energy from waste and thus counts to other/energetic recovery operations whereas a landfill counts towards disposal activities and is the least preferred waste treatment solution (Figure 1).

Figure 1: Waste Hierarchy (own adaption after (European Parliament and Council 2008, Art. 4, 1.))

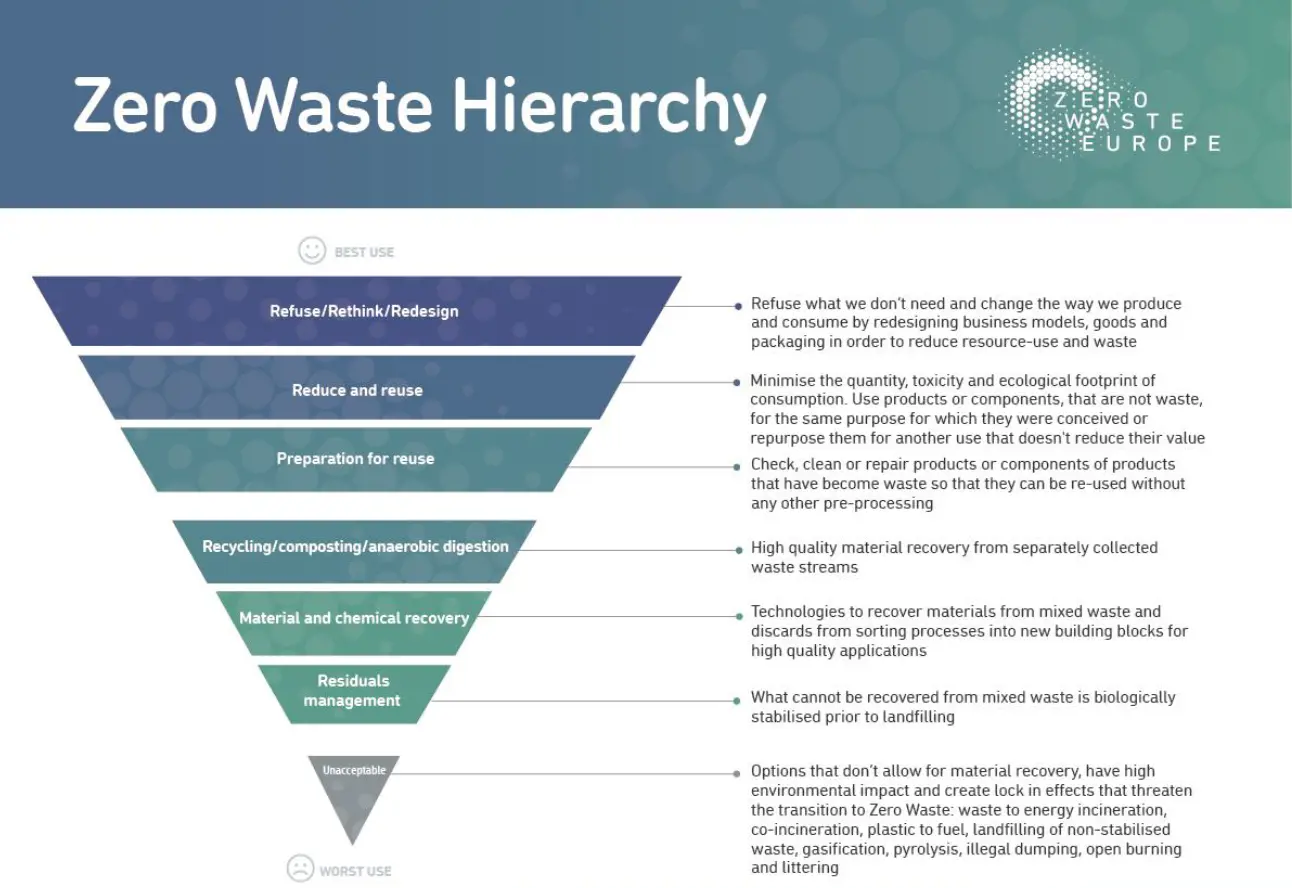

Contrary to that, the zero-waste hierarchy (Figure 2) has many more hierarchical steps (like e.g., redesign, reduce) to be accomplished before a treatment (e.g., recycling, recovery of materials) of waste is even to be considered. If all these steps really would be fulfilled, then WtE as one option that don’t allow material recovery (like also landfilling, gasification, pyrolysis and littering) can be listed as “unacceptable”. However, also if a product is now considered harmless and designed for recycling, in the future it could be considered as harmful – Zero Waste Europe doesn’t show solutions in this case even though WtE is a final sink for non-recyclable material (competing against unwanted solutions like landfilling).

Figure 2: Zero Waste Europe Waste Hierarchy (Zero Waste Europe (Vahk, J.) 2021)

Of course, the combustion of waste plastics will release fossil CO2, but the saved emissions from the displaced fossil fuels are offsetting, and this is especially relevant for high-efficient WtE facilities. A LCA analyses from a Portuguese team even showed that 1 ton of waste saves up to 1.3 Mio. kg of resources and materials (coal, gas, …) and has a negative global warming potential of -171 kg CO2-eq.

It has to be taken into consideration, however, that a certain amount of waste generation goes hand in hand and is a consequence of consumption and economic activity despite the undoubtable fact that MSW generation should be the main goal of individual and industrial behaviours and public policy. Even the well- developed most sophisticated programs for waste reduction, collection and treatment cannot prevent forming a (insignificant) residual waste stream which is often neglected by the Zero Waste philosophy. Even if material is collected separately, it can sometimes only be recycled to a limited extent. Also, harmful contaminants are always collected alongside and have to be segregated. The only options to protect public health are final treatments like WtE. Thus, WtE are not competitors to recycling but compatible partners also in to treat residual waste in an environmentally sound manner as “kidney function”.

Not Waste to Energy encourages a higher waste production but a higher per capita consumption increases the generation of waste. But even with a well-established separate waste collection system and high recycling rates, a modern sustainable recycling society comprises of recycling and also energy recovery from waste because various waste fractions are accumulated at the recycling processes end.

Furthermore, to establish an adequate and integrated waste disposal network, EU Member States should take into account the principles of self-sufficiency and proximity. This means that geographic circumstances or the necessity of specialised installations should be taken into account when treating waste - it should be treated in the nearest appropriate installation considering the most appropriate technologies and methods to ensure a high-level environmental and public health protection.

Per 1.000 kg of waste incinerated ca. 230-280 kg of ashes (= ca. 25 %) are generated in total, whereof incinerator bottom ash (IBA) is the major stream (approx. 4/5 of the total ashes). Bottom ash (also called grate ash, slag or clinkers) is the non-combustible fraction of waste, it mainly consists of silica, calcium and iron but even gold and silver can be found inside the IBA. Bottom ash from incinerators is not harmful and after certain treatment it can be used in the road building industry or as concrete tiles depending on the legal situation in the country. In many countries in the EU (e.g., Poland, Spain and France) IBA utilisation is permitted and practiced, 60% is utilised outside of landfills e.g. as subbase layer in road construction. The utilisation of IBA is even considered as part of the circular economy.

Only fly ash which is the particulate fine ash fraction from incineration (makes up for approx. 1/5 of the total ashes from the WtE plant, only a few per cent of the total Input into the WtE plant) is a hazardous waste. Its treatment is strictly regulated. According to the Best Available Techniques (BAT) for waste incineration can be mixed with cement and safely stored in (hazardous waste) landfills.FCC WtE plants are operated according to law, using the best available techniques (BAT), and keeping environmental impacts at a minimum.

It is true that flue gas emissions of waste incinerators contain the greenhouse gases and pollutants from the waste, which requires further treatment before emission to the atmosphere. Emissions may include carbon dioxide, nitrous oxide, nitrogen oxides, ammonia, carbon monoxide, volatile organic compounds, persistent organic pollutants (e.g., furans and dioxins) and some heavy metals, which have the potential to harm the environment and human health. In order to prevent and control the environmental impacts of waste incinerators, the Industrial Emissions Directive (IED) sets strict operational conditions, technical requirements and emission limits for industrial activities. All industrial installations, including waste incineration and co-incineration plants in the EU, must have an environmental permit based on the requirements of the IED. Operating permits include binding emission limits for harmful substances.

These limits are based on what can be achieved using the Best Available Techniques (BATs). Which techniques are considered as ‘BAT’ is defined in the binding conclusions of industry-specific reference documents known as ‘BREFs’. Thermal WtE plants with advanced emission control technologies operating according to law have minimum public health impacts.

Recent studies have shown that emissions of toxic pollutants from modern WtE plants have a relatively low environmental impact in comparison to other alternatives of waste disposal or to other industrial activities. Total dioxin/furan emissions of WtE plants decreased significantly, e.g., WtE plants in France decreased their annual dioxin emissions from 435 g TEQ (toxic equivalent) in 1997 to only 1.2 g in 2008. All other industrial emissions of dioxins have also decreased and the major source is household combustion of wood with 320 g TEQ (!). Annual releases of dioxin/furan emissions to air coming from landfill fires were estimated ranging from ca. 50 to 920 g TEQ/year.

All emissions at FCC’s WtE Facility in Austria are measured continuously and online reported to the authority. Furthermore, the citizens can access the continuously measured emission data via FCC ZIDO’s homepage (https://www.fcc-group.eu/de/osterreich/standorte/fcc-zistersdorf-abfall-service-gmbh.html - in German). Depending on the law in each country, even stricter limits could be set. For WtE in Austria emission limits are in principle set by the Abfallverbrennungsverordnung, the Austrian waste incineration directive (BGBl. II Nr. 389 2002), but depending on the flue gas cleaning system lower limits can be set as well. This is also the case for ZIDO, with the dry flue gas cleaning system, it needs to – and does easily - fulfil lower limits.

Dry flue gas treatment technology enable a flue gas treatment without any process water. Hence, there is no polluted water coming from the WtE technology, which would need to be discharged into the surrounding.

Incineration respecting the EU directive causes no pollution to any source of water. FCC strives to minimize water consumption and makes the best use of available water. At the existing WtE plant in Zistersdorf, AT the entire surface water is collected and processed for the use inside the power plant for e.g., cooling down the slag. The small amount of water used to cool down the slag leaves the plant together with the slag and is disposed at sanitary landfills, where the leachate is collected and cleaned in elaborated wastewater treatment plants.

The main wastewater stream leaving the plant is the wastewater from the wet rooms of the offices. This wastewater is fed into the local sewer system.

According to the European Environmental Bureau, “Waste-water-free techniques should be promoted for wet Flue Gas Cleaning (FGC) systems”.

Our plant will be operated according to law, meeting emission limits and requirements using best available techniques in order to achieve a high level of protection of the environment.

The IED 2010/75/EU (Integrated Pollution Prevention and Control—IPPC) aims to “reduce emissions into air, soil, water and land and to prevent the generation of waste, in order to achieve a high level of protection of the environment”. The IED established key requirements for the operation of an incineration plant:

- a minimum combustion temperature and residence time of the resulting combustion products (minimum requirement of 850°C for 2 sec for MSW)

- specific emission limits for: SO2; nitrogen oxide and nitrogen dioxide (NO and NO2); HCl; HF; gaseous and vaporous organic substances expressed as total organic carbon (TOC); carbon monoxide (CO); dust; heavy metals; and dioxins and furans

- a limit of 3% for TOC content of the bottom ashes and slag produced.

Our plant will be operated according to the a.m. law, meeting the set limits and requirements using best available techniques.

All projects, especially the ones with big potential effects on the environment have to be evaluated according to the EU-Environmental Impact Assessment (EIA) Directive and its respective Member State counterparts. In this Directive, in force already since 1985, it is regulated that environmental damage should, as priority, be paid by the polluter and rectified already at source. The EIA shall identify, describe and assess the (in)direct significant effects of a project on:

- Human health and population

- Biodiversity

- Soil, land, water, climate and air

- Landscape, cultural heritage and material assets

- Interaction of above-mentioned factors.

For each single project, a detailed EIA report has to be elaborated and the competent authorities as well as the public concerned have the right to give their opinion during the process. As this is an evaluation of the current status (before development consent is given) as well as the expected future status, a comparison between effects before and after installation of the project can be made. In case of FCC’s WtE plant in Zistersdorf, Austria, the EIA required the relocation of earth bees which lived in the former brick plant to an artificially constructed clay pit. The environmental inspection to be done every 5 years showed that the bees are now even happier in the new relocation and that the project is the life’s achievement of the controller.

The fact that birds and insects or certain plants have disappeared is true, but certainly not due to the activities of incinerators. This phenomenon is not only characteristic of the surroundings of incinerators but also of the wider territory of Europe.

There are a lot of different factors that cause the decline of birds, insects and certain plants:

- use of chemicals and pesticides in the environment,

- less and less crops are grown in big monocultures which means less suitable food for insects,

- insect predators which benefit from warmer climate,

- habitat fragmentation, which is quite often caused by increasing urbanization,

- increasing insulation of houses which means no nesting possibilities for birds.

The delivered waste is transferred only inside the acceptance hall, where it is filled into the bunker where enough storage capacity is considered. The air of the bunker as well as the acceptance hall is sucked and used for the combustion process. The controlled sub-atmospheric pressure in the bunker, acceptance hall and the gate ways, which only open for deliveries, prevent smelly air from leaving the plant. The sucked air is burnt together with the waste and passes the highly elaborated flue gas treatment. In normal operations, no odour leaves the plant, neither from the input nor the output streams.

Also, during shut downs the air is sucked via an emergency sucking system and treated with an active coal and dust filter.

For FCC AT’s WtE plant in Zistersdorf, waste is delivered, among others, from FCC’s treatment location in Himberg where enough storage capacity is considered. During a regular shutdown of Zistersdorf the majority of the waste is stored in Himberg in the form of properly sealed bales as the bunker in Zistersdorf would not have enough storage capacity. If waste is delivered to Zistersdorf (e.g., from the surrounding municipalities), it is directly transferred to the bunker and not stored outside of the plant which is also a requirement of the BAT regulation.

Incineration plants can be located close to residential areas, which are the centres of production of waste, and this helps to reduce the volume of traffic, pollution, noise and of course the costs for the waste transportation (see also following Myth (5.1.4)). Between 2009 and 2021, our operators of the WtE facility in Zistersdorf recorded only 2 neighbour complaints about odour. Whether the polluter was the nearby wastewater treatment plant, the delivering trucks or the waste bunker could never be determined.