Drainage cleaning for pipelines in arterial roads of streets and railways

Tunnels all over the world are equipped with drainage systems, for the draining-off of water which accumulates inside the tunnels. However, these drainage systems can become clogged or incrusted due to chalky sediment in the water, especially for example, in mountainous regions.

in the water, especially for example, in mountainous regions.

This can quickly have negative consequences for the drainage system, such as the reduction of the pipes’ cross section - which diminishes the capacity to drain the water away, or indeed causes clogging of slots and pipe openings and results in the leakage of water back into the tunnel.

Therefore, to ensure proper and safe tunnel operations, it is important to keep tunnel drainage systems clean - which in itself constitutes a significant proportion of our customers’ tunnel maintenance costs.

To be able to clean the (tunnel) drainages, several possibilities exist on the market which are covered by FCC and can be operated internationally.

1. Suction truck on train waggon

Mounted on a train waggon the suction truck can be used for the cleaning of tunnel drainage pipes which is also the standard-technology currently in use. Cleaning is possible for lengths up to 300 m, however, the tunnel operations are blocked during the cleaning interval.

2. High-Pressure pipe cleaning system HIPPO

In 2016, the Austria’s national railway provider - ÖBB, published a tender for the cleaning of tunnel drainage systems with reduced interruption intervals of tunnel operations. FCC won the tender and has been cleaning the drainage systems of ÖBB’s railroad tunnels since November 2017, using our High-Pressure Pipe Cleaning System - HIPPO - which was especially developed to fulfil our customers’ unique requirements.

Our solutions

HIPPO 600

The HIPPO 600 was originally custom developed for the ‘Wienerwaldtunnel’ (Vienna Forest Tunnel), close to Vienna in Austria, but it is a flexible system which can also be used in several different types of drainage pipe systems.

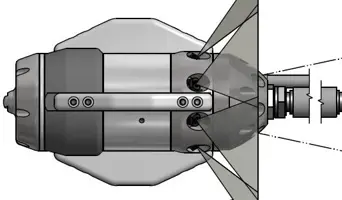

HIPPO makes sure that the water which accumulates on the walls of tunnels is safely drained away through clean and well-maintained pipes. HIPPO achieves this through cleaning the pipes using a high-pressure water ejecting nozzle. A camera which is built into the nozzle allows the inspection of conditions within the pipe, as well as a complete recorded documentation of the cleaning process.

The system also offers another great advantage - that tunnel operations can be continued almost entirely without interruption (tunnel closure is only necessary if the tunnel is longer than 600m, and only then during the setup and dismantling of the system). Naturally, this offers a great incentive in terms of cost reduction for our customers.

Besides the visual nozzle, the HIPPO can also be equipped with a robot unit. Therefore, this modular technology can be operated flexibly and is even able to perform minor maintenance jobs and repairs within the pipe systems, if required.

Due to the complex and often unique tasks that HIPPO undertakes, as well the high safety standards that need to be maintained in tunnels, HIPPO was and is continuously being adapted and improved. The System can be operated in nearly all drainage pipes due to its quick set-up time and intuitive modular design. In case of occurring problems, necessary components can be easily changed.

As mentioned earlier, HIPPO can clean round (tunnel) drainage pipes with a length of up to 600m. However, it can also be utilised in other areas too - wherever drainage pipes are installed that require continuous and regular cleaning.

Advantages for you as our customer:

Flexible system with operation in many areas (nearly all pipe systems)

- Only short interruptions of the tunnel operations from lengths more than 600m necessary – significant cost reduction

- Cleaning and documentation are done in one step

- Highly water resource saving technology

- Technology successfully proven in many tests

HIPPO 1500

Between 2018 and 2022, FCC participated in the 30-month EU Horizon 2020 Shift2Rail Joint Undertaking, also known as ‘Assets4Rail’.

During this EU project, the HIPPO 600 was upgraded to the HIPPO 1500, with the new longer distance HIPPO still keeping all of the advantages of the 600m equipment. Under non-optimal

Advantages for you as our customer:

Flexible system with operation in many areas (nearly all pipe systems)

- Even shorter interruptions of the tunnel operations from lengths more than 600m necessary – even higher cost reduction

- Cleaning and documentation are done in one step

- Highly water resource saving technology

- Even longer operational lengths

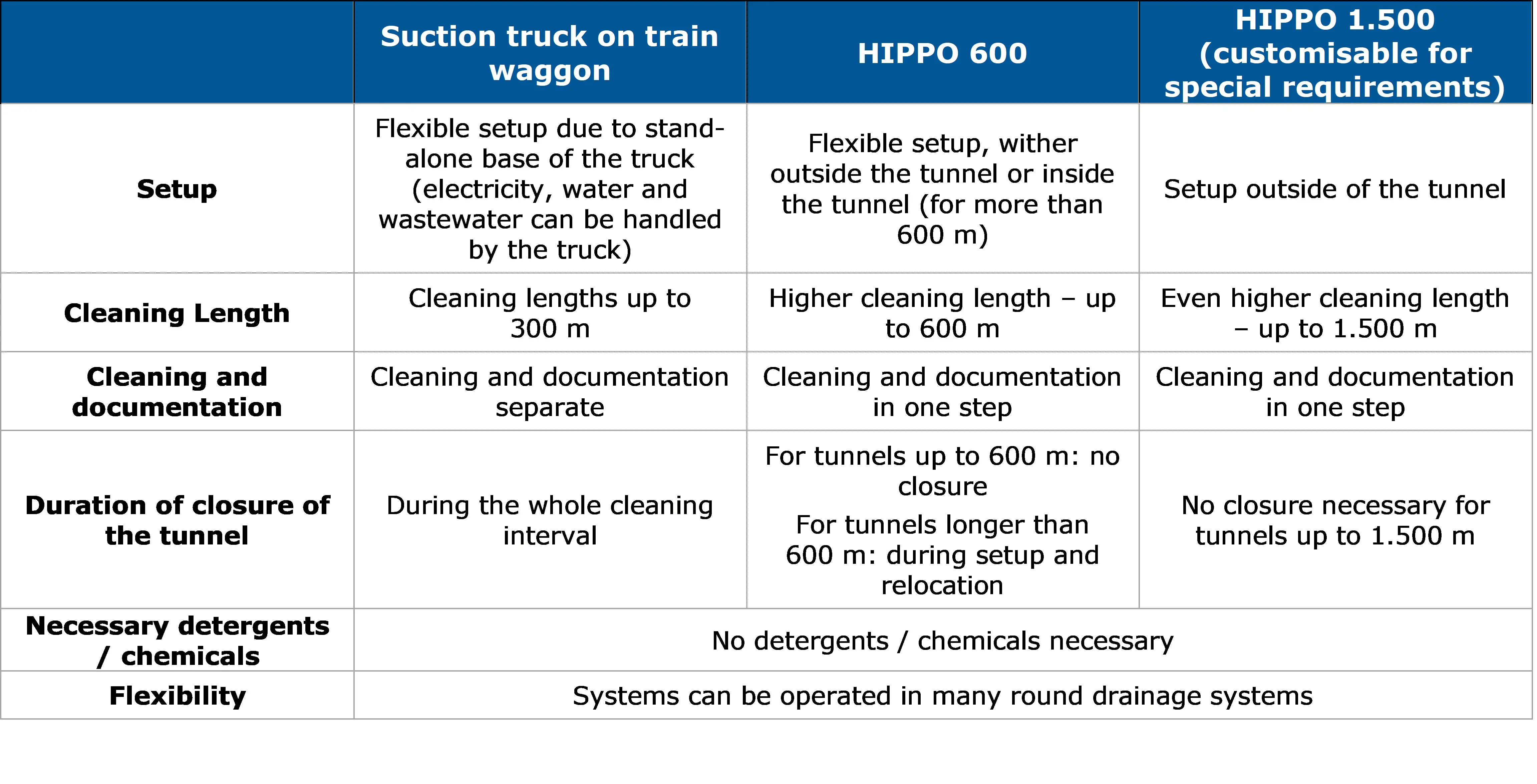

Overview and advantages of the offered technologies for the cleaning of (tunnel) drainage pipes

Your contact person:

Mag. Jochen Pach, MEng.

Key Account Sales

Auer-Welsbach-Gasse 25

A-8055 Graz

Tel.: +43/316/29 27 91-3132

Mobil: +43 664 358 45 67

Mail: jochen.pach@fcc-group.at